(800) 922-0118

(800) 922-0118sales@swissjewel.com

(800) 922-0118

(800) 922-0118

Synthetic sapphire bearings and ruby bearings, because of their hardness and ability to accept a high polish, are recognized universally as the ideal jewel bearing material for instruments, meters, control devices and other precision mechanisms where low friction bearings, long life and dimensional accuracy are important. Ranking next to diamond in hardness, synthetic sapphire is identical in chemical composition to natural sapphire, but is a far superior jewel bearing material because impurities and flaws are eliminated. Jewel bearings are used in a range of industry applications. Swiss Jewel has been a leading jewel bearing manufacturer of sapphire bearings for over 100 years.

Contact us to learn how we can help with all your jewel bearing needs, including custom jewel bearing designs!

Ring Jewel Bearings serve as radial or sleeve jewel bearings used with straight cylindrical shafts. They offer flexibility in jewel bearing design through many possible combinations with endstones.

Ring Jewels can be mounted into bushings or screws. This style can ease your mounting of the jewel bearing into your final instrument.

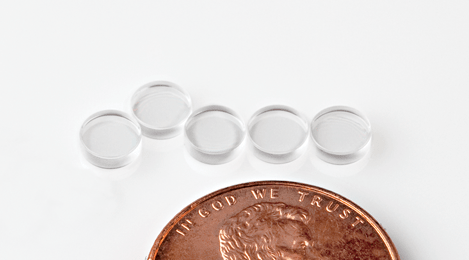

Endstones find wide use as a thrust bearing in combination with a ring jewel which serves as the annular jewel bearing.

Endstones find wide use as a thrust bearing in combination with a ring jewel which serves as the annular jewel bearing.

Vee Jewel Bearings are well suited to sensitive instruments where the moving element is light.

Vee Jewel Bearing Assemblies are typically mounted in screws. This style can ease your mounting of the vee jewel bearing into your final instrument.

Cup Jewels are generally used with a semi-spherical pivot or in a jewel bearing design that fits a ball bearing between two cup jewels.